21 1 月 2026

For over fifty years, Itap has been designing and manufacturing ball valves for civil, industrial, and gas systems.

There are products that tell the story of a company better than any slogan.

For us at Itap, ball valves do just that. They represent the outcome of precision, control, responsibility and continuous research.

They are the core of our production capabilities and are engineered to meet the needs of civil, industrial and gas applications.

Used in millions of applications worldwide, Itap valves ensure safety, reliability and easy installation.

But what lies behind a component that, at first glance, looks so simple?

A ball valve is small and compact, yet indispensable. Inside, it contains everything needed to ensure the safe operation of a system.

How do our valves differ from the many available on the market?

Two key technical features make our valves unique:

But our true strength lies in our production process: a method that ensures consistent quality and full traceability of each individual unit.

Quality begins with the selection of raw materials: the brass alloy is a decisive factor in ensuring efficiency and durability of our finished product.

After a thorough and technical selection, the material is hot‑forged to obtain bodies and sleeves. Even at this stage, components undergo the first quality checks in our laboratories.

Once approved, they go through sandblasting, which ensures uniform surface finishing.

After these steps, the mechanical processing is carried out using high‑precision transfer machines, which perform drilling, threading, washing and all other necessary steps with excellent repeatability.

At the same time, the other valve components are produced.

Stems are made from calibrated brass bars, then cut, washed, and equipped with their seals. This is a crucial step, given the stem’s importance in ensuring tightness and safety.

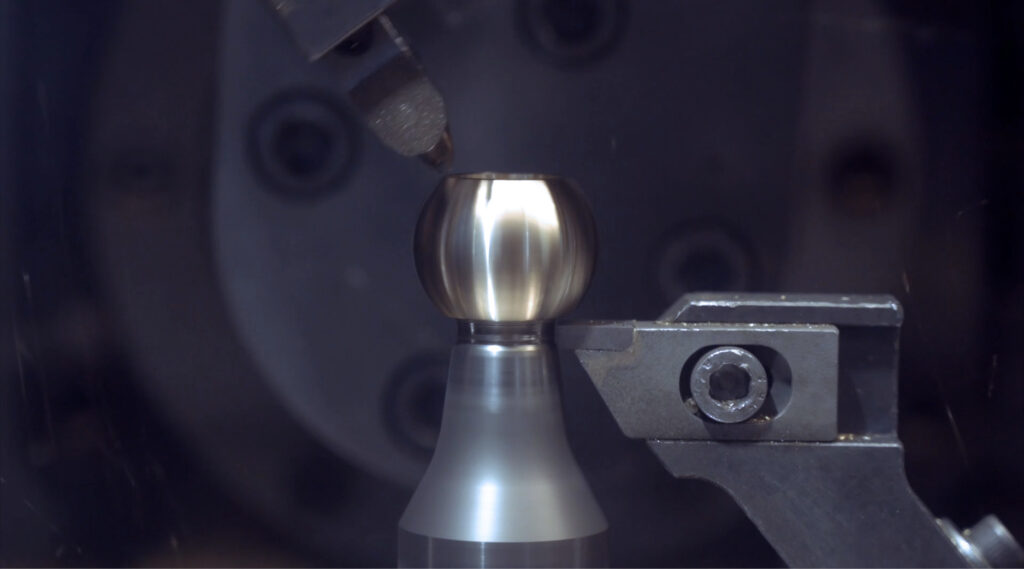

The balls, instead, are milled and polished with dedicated machinery to ensure smooth operation, long‑lasting resistance and reliable performance even under high pressure.

All assembly stages are managed by automated and digitally controlled lines:

Each component is tracked and verified through every step to meet international safety and performance standards.

Behind the 8 million ball valves produced each year, there is an industrial culture built on innovation, precision and the enhancement of human skills.

At Itap, machines do not replace operators, they support them and amplifying their expertise.

It’s this human–tech balance that allows us to consistently deliver excellence, innovation and long–term reliability.

To see the stages of our production process, you can watch the dedicated video on our YouTube channel.

How is a ball valve made? Discover the full video.

At Itap we produce 7 families of ball valves, designed to meet the diverse needs of professionals in the field:

1 – Working with potable water?

Green DVGW and Ideal DVGW for drinking water.

Certified EN 13828 and DVGW W 570, full bore flow and a ball designed to avoid stagnation and prevent diseas like legionella.

It’s a responsible choice for safe drinking water.

2 – Looking for high flow, pressure, and reliability?

Madrid and Paris offer full bore, nickel‑plated brass and withstand pressures up to 50 bar.

The Paris model, with its stamped steel lever, is ideal where a compact yet robust handle is needed.

3 – Working in tight spaces?

Vienna and Orient meet the needs of manifolds and internal systems.

Standard or reduced bore, compact design and levers shaped to avoid interference during operations.

4 – Installing gas systems?

London and Berlin comply with EN 331, offer a maximum temperature of +60 °C and standard pressure of 5 bar, avaible in verisons up to 18 bar.

They are easily recognizable thanks to their yellow handle, an extra visual safety feature during installation.

5 – Need a different lever type?

Efficiency also depends on choosing the right handle. We offer many variants: red, blue, black, yellow, flat, or butterfly‑style, in various materials to suit any application.

Itap ball valves are not just technical components: they are an integral part of simple and complex systems in more than 108 countries. Their reliability stands out in projects where quality, safety and operational continuity are essential requirements.

Across numerous projects worldwide, it is possible to see concrete examples of how our valves are used in high-responsibility contexts, such as large office buildings, hospitality and healthcare facilities, and international residential developments.

Among the most significant applications are:

A ball valve is a universal component, and it is often found in unexpected applications, such as:

These examples show how a seemingly simple component can play a vital role in the success of a system.

The ability to operate continuously, withstand variable load conditions and integrate seamlessly into complex systems is the foundation of professionals’ choice of our products.

Thanks to:

Our ball valves provide a concrete response to the needs of the market, designers and installers.

It is not just about producing individual components, but about delivering reliable solutions capable of supporting anything from small domestic systems to large-scale public infrastructure projects.

Discover our full range of ball valves and gas valves.

They are mainly distinguished by two technical elements:

Production begins with the selection of the brass alloy, which is hot‑forged to create the main components. The process continues with:

Each component undergoes quality checks right from the early stages.

Itap offers 7 families of ball valves to meet professional needs:

Several lever variants are also available to suit any installation.