- Produits

- VANNES

- CLAPETS ANTI-RETOUR ET CLAPETS AVEC CRÉPINE

- VANNES À BOISSEAU SPHÉRIQUE ET VANNES À OPERCULE

- ROBINETS DE DISTRIBUTION

- VANNES À BOISSEAU SPHÉRIQUE POUR GAZ ET DISPOSITIFS DE SÉCURITÉ POUR GAZ

- ROBINETS À ENCASTRER ET SOUS LAVABO

- ROBINETS BRANCHEMENT MACHINE À LAVER

- ACCESSOIRES POUR INSTALLATIONS THERMIQUES SOLAIRES

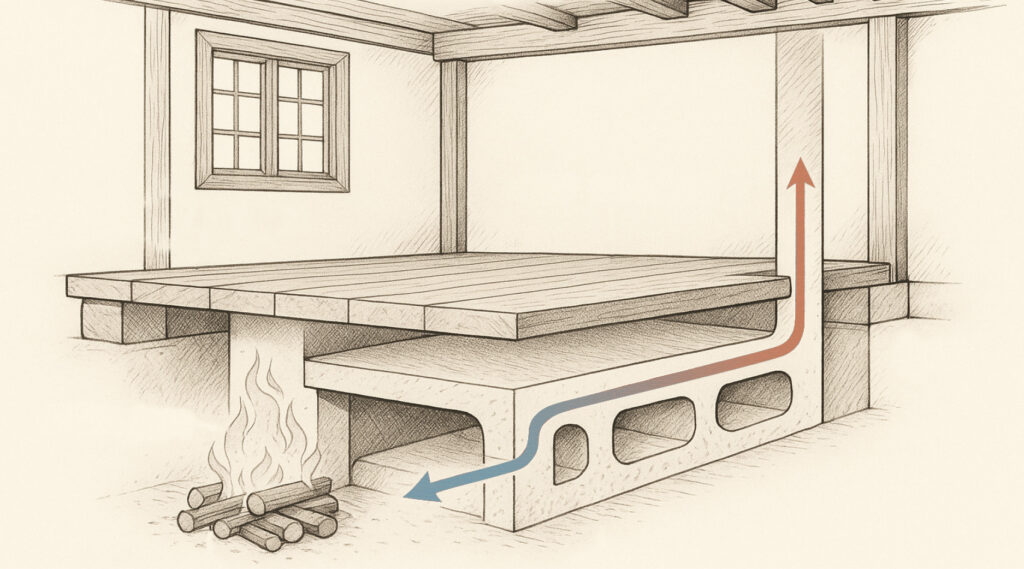

- CHAUFFAGE

- VANNES THERMOSTATIQUES ET COUDES DE RÉGLAGE

- COMMANDES THERMOSTATIQUES

- VANNES MANUELLES ET COUDES DE RÉGLAGE

- RÉPARTITEURS POUR ROBINETTERIE INTÉGRÉE

- SERVO-COMMANDES ET VANNES DE ZONE À BOISSEAU SPHÉRIQUE

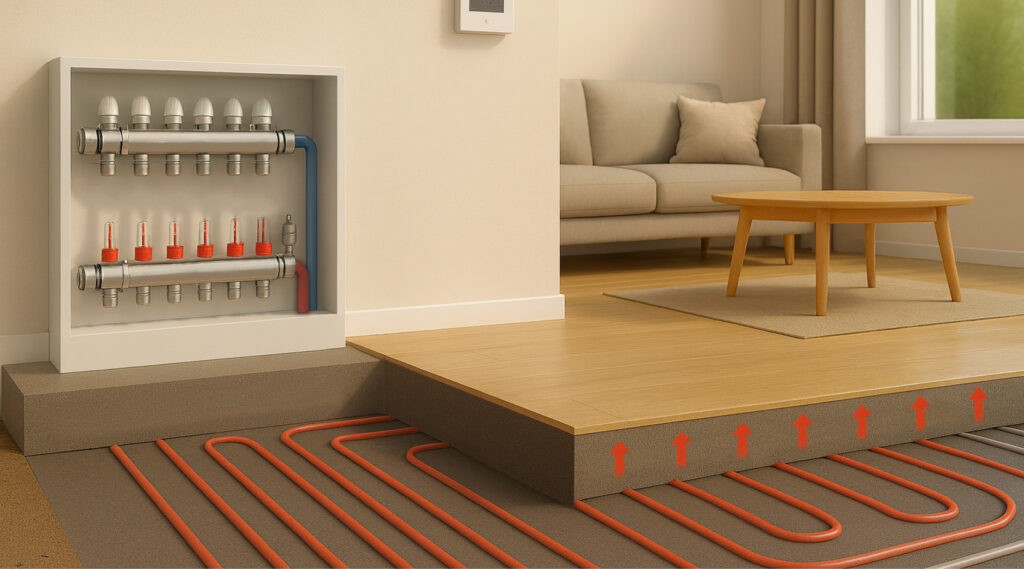

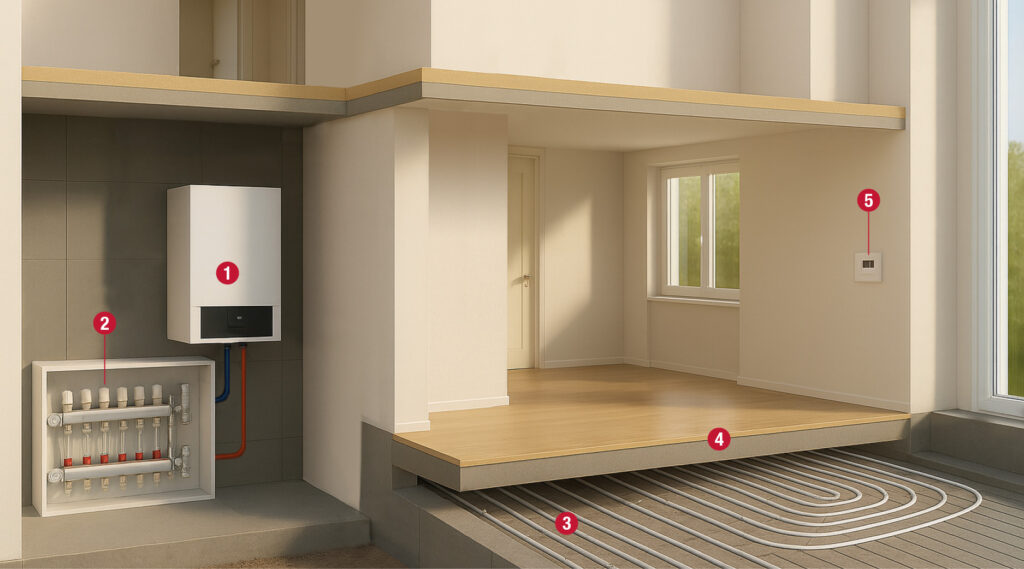

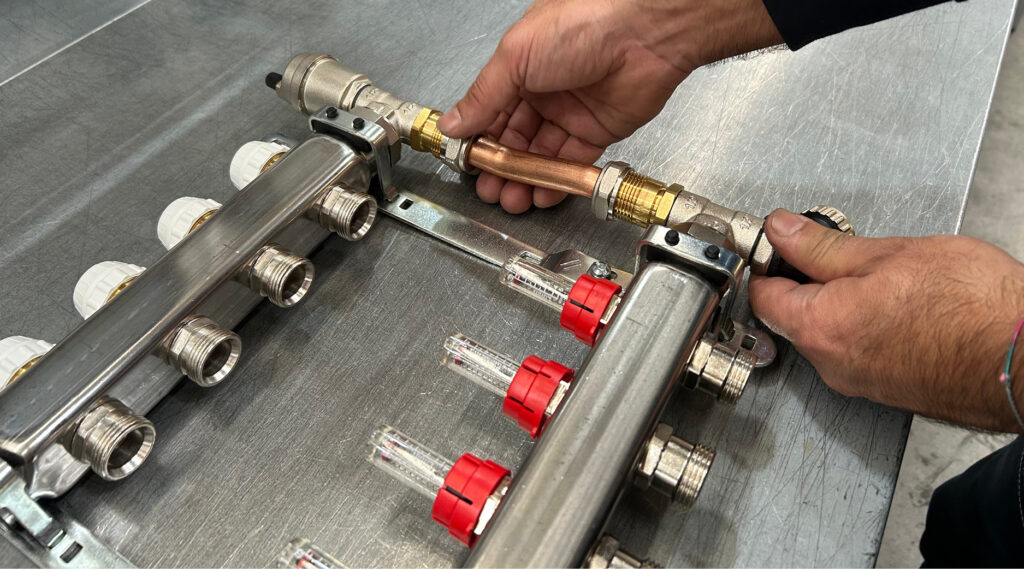

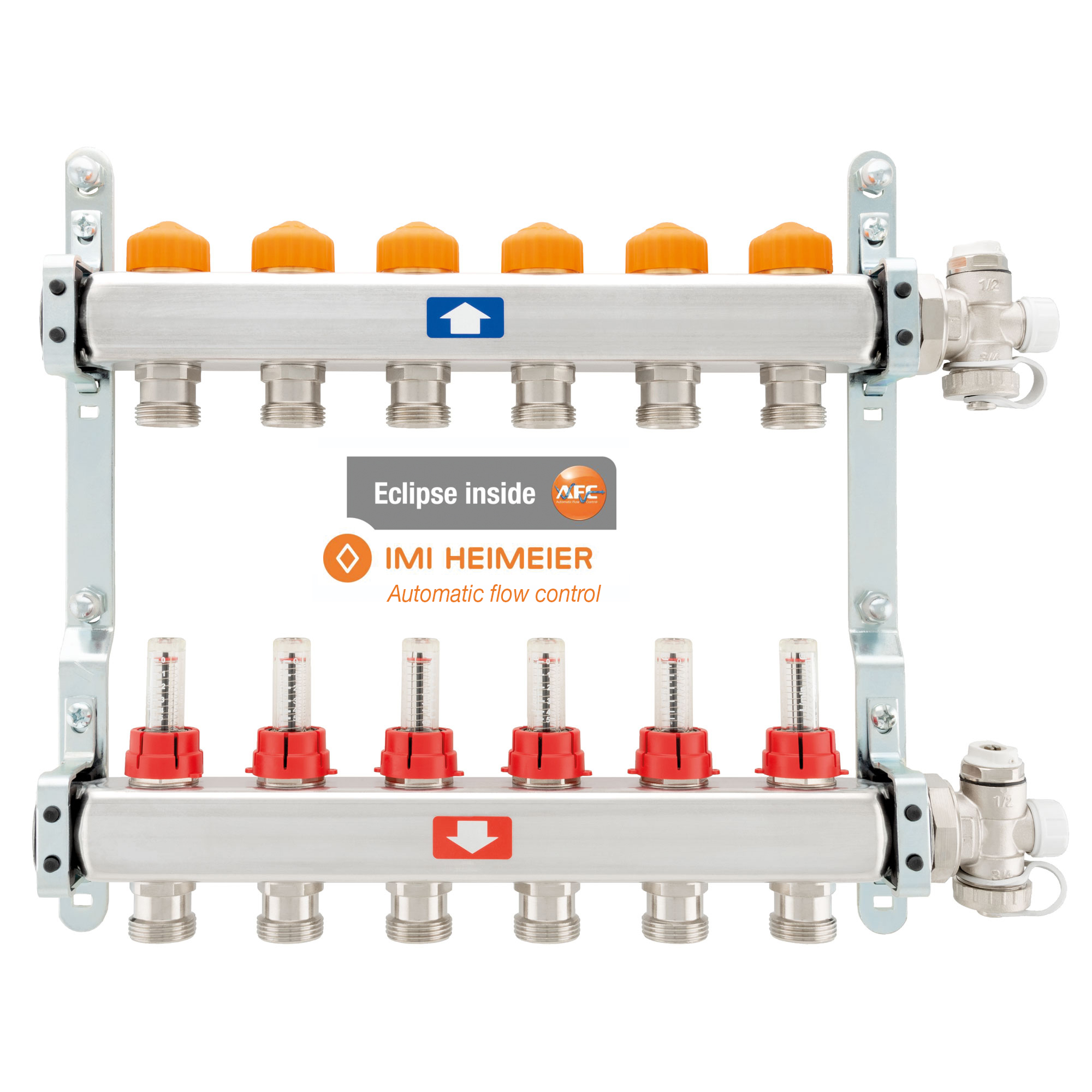

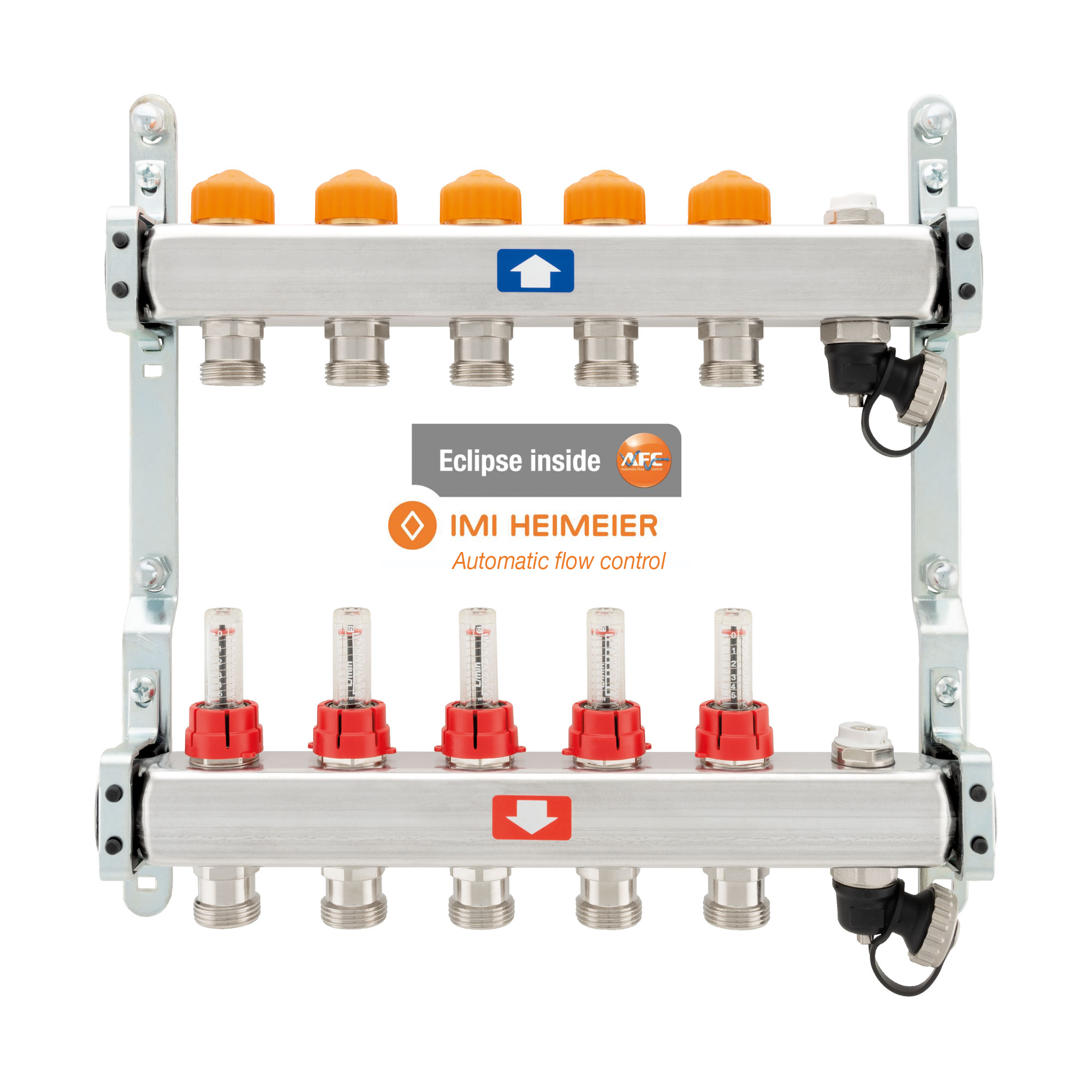

- COLLECTEURS DE DISTRIBUTION

- COLLECTEURS EN ACIER INOXYDABLE

- COLLECTEURS EN LAITON

- KIT D’UNITÉ DE RÉGULATION

- ACCESSOIRES POUR COLLECTEURS

- PURGEURS ET SOUPAPES DE SÉCURITÉ

- UNITÉS DE DISTRIBUTION ET COLLECTEURS POUR INSTALLATIONS DE CHAUFFAGE CENTRAL

- THERMOSTATS ET CHRONOTHERMOSTATS

- RACCORDS

- FILTRES

POTS DE DÉCANTATION AVEC AIMANTS

RÉDUCTEURS DE PRESSION

- VANNES

- EN ÉVIDENCE

- Catalogue

- Telechargement

- Certifications

- Portfolio