- VALVES

- HEATING

- CONVERTIBLE VALVES AND LOCKSHIELDS

- THERMOSTATIC CONTROL HEADS

- MANUAL VALVES AND LOCKSHIELDS

- TWO-PIPE VALVES FOR PANEL RADIATORS

- ELECTRIC ACTUATORS AND ZONE BALL VALVES

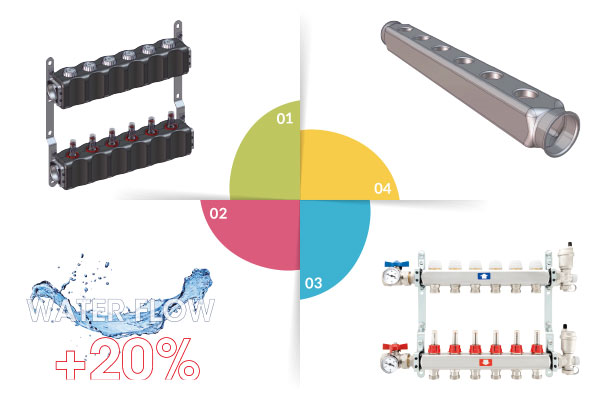

- DISTRIBUTION MANIFOLDS

- STAINLESS STEEL MANIFOLDS

- NICKEL-PLATED MANIFOLDS MADE OUT OF BRASS BAR

- SET POINT REGULATING UNIT

- ACCESSORIES FOR MANIFOLDS

- AIR VENT VALVES AND SAFETY VALVES

- DISTRIBUTION UNITS AND MANIFOLDS FOR CENTRAL HEATING PLANT

- THERMOSTATS AND CHRONOTHERMOSTATS

- FITTINGS

- STRAINERS – DIRT SEPARATORS – PRESSURE REDUCING VALVES

- Highlights

- Catalogue

- Blog

- Virtual Tour